Mekanik Tasarım

Yapısal Tasarım

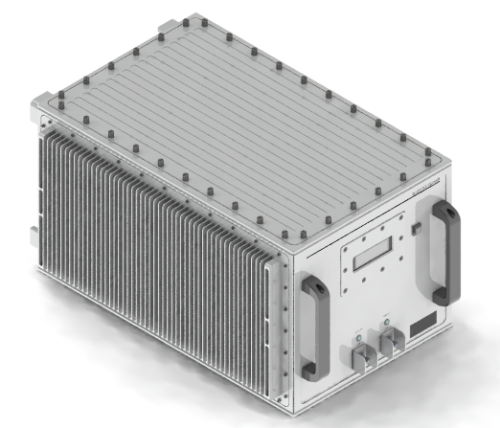

Mekanik tasarım kabiliyetimiz ile her türlü mekanik parça sistem, makine gereksinimlerine ve tasarım tanımlarına uygun olarak üç boyutlu katı model olarak tasarlanır, gerekli analizler (CFD, Thermal Analysis, Static) yapılır ve nihayetinde üretim resimlerine dönüştürülür.

Tasarım sürecinin tamamlanmasıyla, oluşturulan tasarım dokümanlarına uygun olarak prototip üretimleri gerçekleştirilir. Bu üretimler sırasında yapılan tasarımın üretime uygunluğu değerlendirildiği gibi detaylı üretim dokümanları da hazırlanır.

Test ve doğrulama prototip üretimi gerçekleştirilmiş Sistem/Birim’lerin gereksinimlere uygunluğu doğrulanır. Bu doğrulama faaliyetleri içerisinde firmamız bünyesinde yapılan testler olduğu gibi eğer arzu edilirse hizmet alımı yoluyla yurtiçi ve yurtdışı laboratuvarlarda yapılan testler de bu kapsamda yer alabilir.

Doğrulama faaliyetleri her bir gereksinimin nasıl doğrulanacağını gösterecek şekilde özenle hazırlanmış test ve doğrulama dokümanlarına uygun olarak gerçekleştirilir ve raporlanır.

Dokümantasyon kabiliyeti ile proje teslimat kalemlerine ve konfigürasyonlarına uygun olarak aşağıdaki dokümanlar titizlikle hazırlanarak müşteriye teslim edilir.

• Gereksinim Tanımlama Dokümanı

• Tasarım ve Test Tanımı Dokümanları

• İmalat Dokümanları

• Doğrulama ve Kalifikasyon Talimatları

• Kabul ve Muayene Talimatları

Web Tasarım & Yazılım UX Ajans Yazılım & Medya